cutting mount board

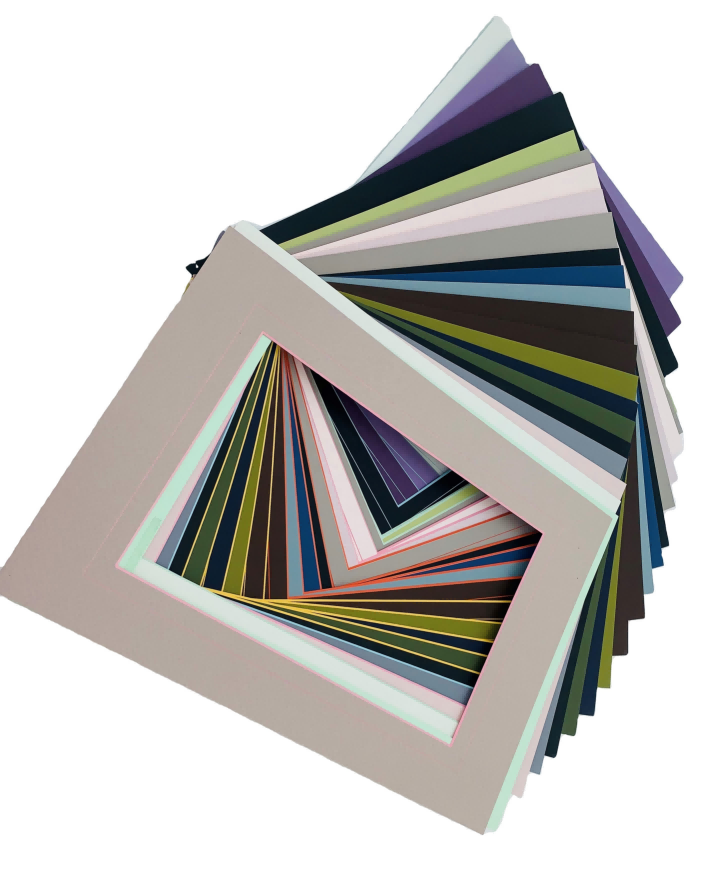

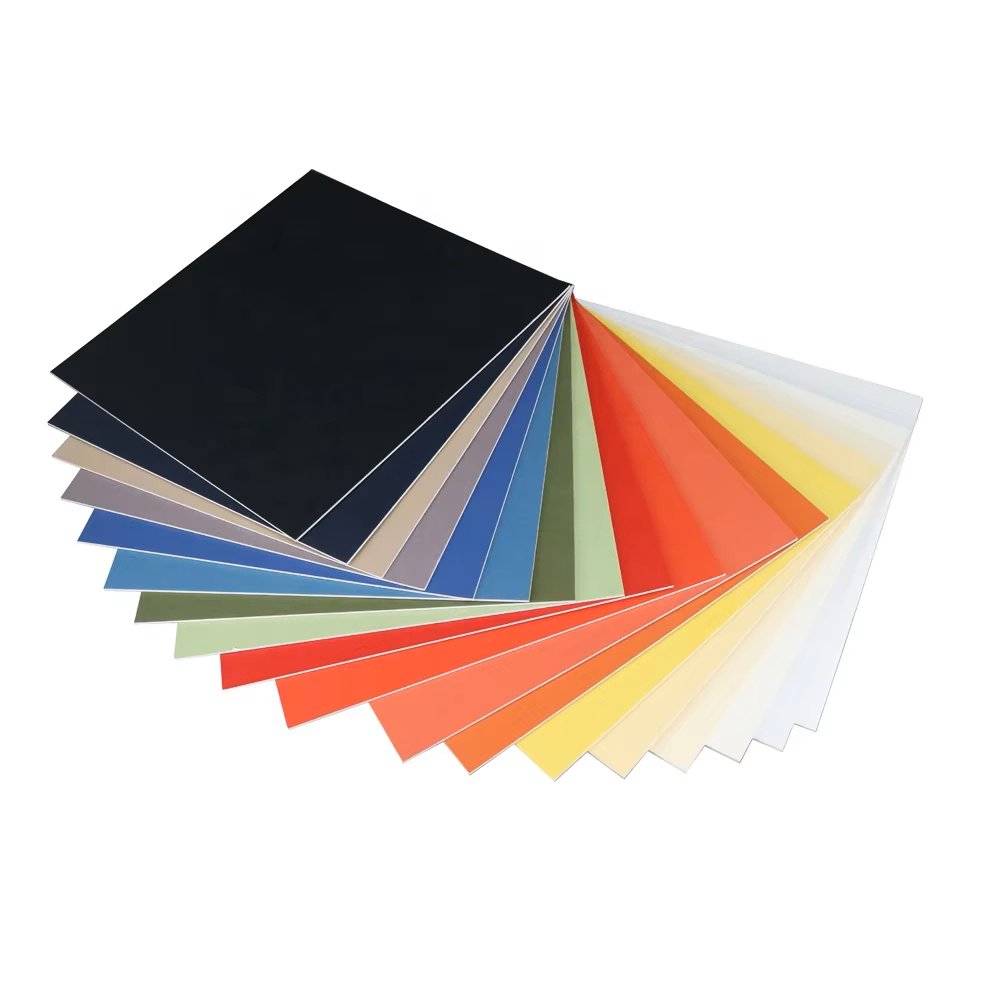

A cutting mount board is an essential tool in professional framing and artwork presentation, engineered to provide precise and clean cuts for mounting materials. This versatile board features multiple layers of high-quality paper compressed together, creating a rigid and durable surface that maintains its structural integrity over time. The board's composition typically includes a core layer sandwiched between two surface layers, offering superior stability and resistance to warping. Modern cutting mount boards are manufactured using advanced production techniques that ensure consistent density and thickness throughout the material, making them ideal for both hand-cutting and machine-based applications. The surface is specially treated to prevent yellowing and maintain color integrity, while the core is designed to produce clean, sharp edges when cut. These boards come in various thicknesses, typically ranging from 1.4mm to 3.0mm, allowing users to select the most appropriate option for their specific mounting needs. The technological advancement in their production ensures minimal fiber tear during cutting, resulting in professional-grade presentation quality that meets museum and gallery standards.