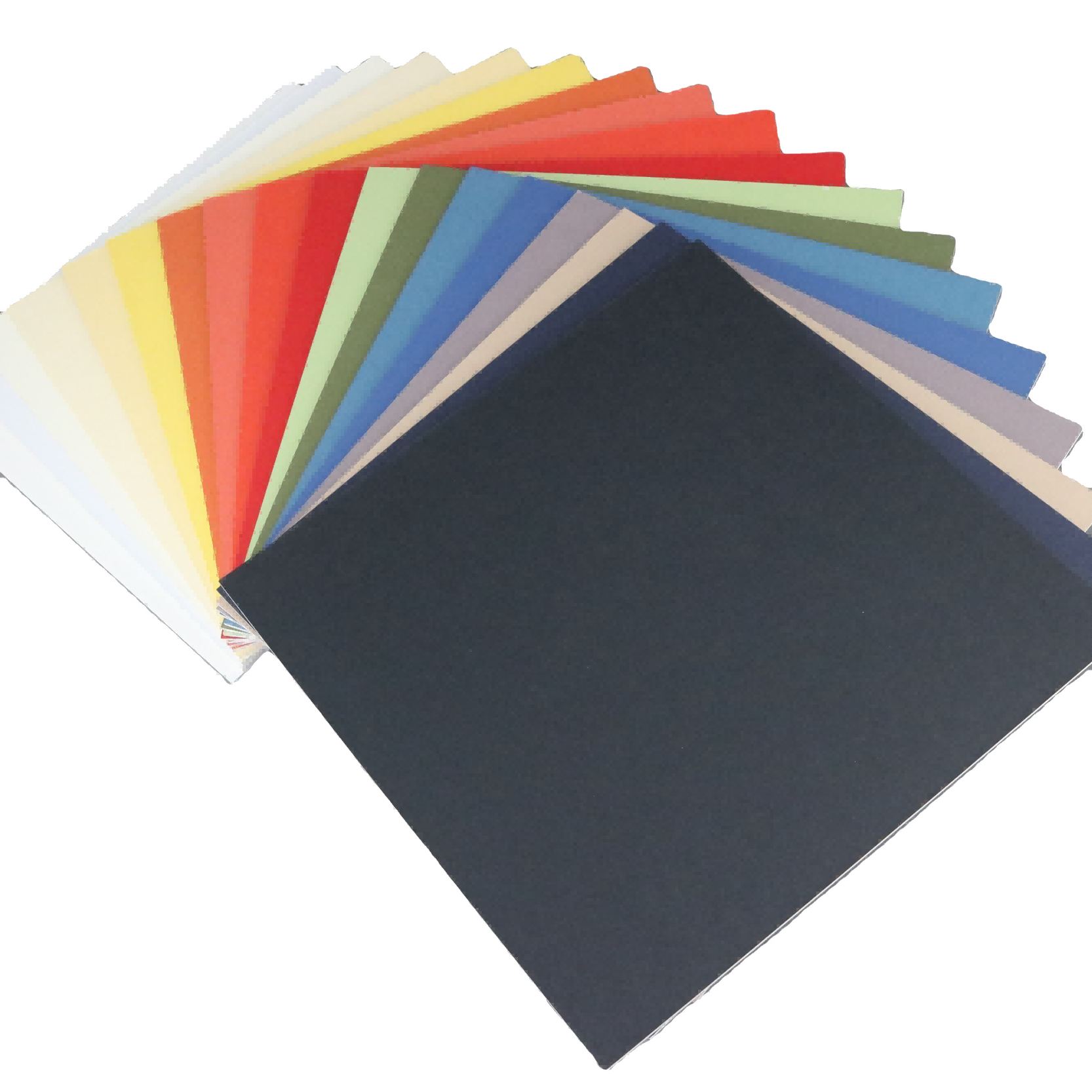

custom cut mat board

Custom cut mat board represents a professional framing solution that combines precision engineering with aesthetic versatility. This specialized material is manufactured using high-quality, acid-free components that ensure long-term preservation of artwork and photographs. The board is precisely cut to specific dimensions using advanced computerized cutting systems, resulting in clean, sharp edges and perfectly aligned openings. Available in various thicknesses ranging from 2-ply to 8-ply, custom cut mat boards can be tailored to accommodate different frame depths and artistic requirements. The material's core is designed to prevent warping and maintain structural integrity over time, while its surface is treated to resist fading and discoloration. These mat boards come in an extensive range of colors, textures, and finishes, allowing for creative freedom in presentation design. The precision cutting technology enables the creation of complex designs, multiple openings, and decorative effects that enhance the visual impact of the framed piece. Whether used for museum-quality displays, professional photography presentations, or home decor, custom cut mat boards provide both protective and decorative functions while maintaining archival standards.